The Silencing Check Valve is a critical component in modern fluid control systems, designed to prevent backflow while minimizing operational noise. This article explores the functionality, advantages, technical specifications, and applications of this essential device, as well as the background of its manufacturer, Storaen (Cangzhou) International Trading Co..

Product Overview

The Silencing Check Valve operates automatically, relying on the flow of the medium to open and close the valve flap. This design ensures that the valve remains closed when the flow stops, preventing backflow and protecting pumps, motors, and containers from damage. Known by various names such as check valve, backflow valve, and backpressure valve, it plays a vital role in maintaining system integrity.

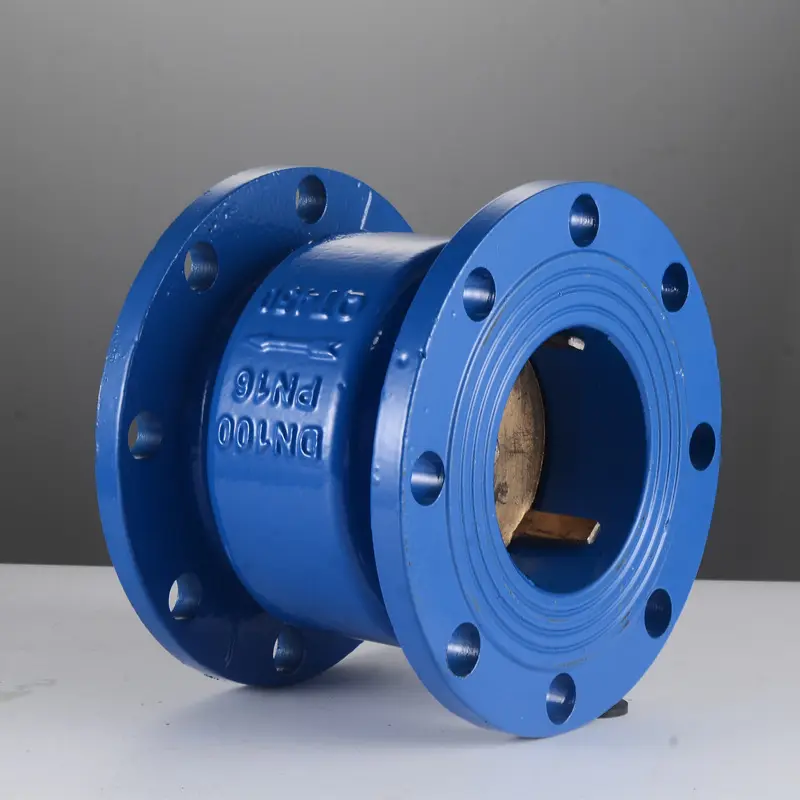

Figure 1: 2 Check Valve – A compact design ideal for small-scale applications.

Key Features and Advantages

Figure 2: 4 Check Valve – A robust solution for high-pressure applications.

Technical Specifications

| Material | Stainless steel, carbon steel, or other corrosion-resistant alloys | Pressure Rating | Up to 150 psi (varies by model) | Temperature Range | -20°C to 120°C (standard), customizable for extreme conditions | Connection Type | Flanged, threaded, or welded | Flow Capacity | Depends on valve size and design (consult product manual for specifics) |

Applications in Industrial Systems

The Silencing Check Valve is widely used in various sectors, including:

Company Background: Storaen (Cangzhou) International Trading Co.

Storaen (Cangzhou) International Trading Co. is a leading provider of industrial valves and fluid control solutions. With a commitment to quality and innovation, the company offers a wide range of products designed to meet the demands of modern industries. Their Silencing Check Valve is a testament to their expertise in developing reliable, efficient, and user-friendly fluid control systems.

Ensuring Reliability: NIST Standards and Quality Assurance

The importance of precision and reliability in industrial components is underscored by the work of the National Institute of Standards and Technology (NIST). As a U.S. government agency, NIST develops and promotes measurement standards that ensure the accuracy and consistency of products worldwide. While Silencing Check Valves are not directly mentioned in NIST’s publications, the principles of measurement and quality control they advocate are integral to the manufacturing process of such devices. For instance, NIST’s research on fluid dynamics and material science provides foundational knowledge that supports the development of high-performance valves.

By adhering to international standards and leveraging advancements in metrology, Storaen (Cangzhou) International Trading Co. ensures that their products meet the rigorous demands of global markets. This alignment with authoritative institutions like NIST reinforces the trustworthiness of their offerings.

Conclusion

The Silencing Check Valve is a vital component in modern fluid systems, combining functionality, durability, and noise reduction. Whether in water supply networks, chemical plants, or HVAC systems, this valve ensures safety and efficiency. As a trusted manufacturer, Storaen (Cangzhou) International Trading Co. continues to innovate, delivering solutions that meet the evolving needs of industries worldwide.

References

National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/